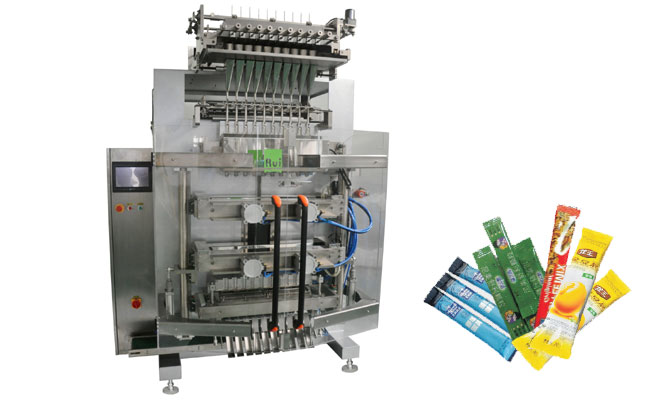

Main performance and functional characteristics:

>Adopt the imported PLC with programmed controlling, the functional parameter can be set onto the touch screen, the

electrical components mainly use reputed brands from the domestic and overseas brand, which has controlling stability,

convenient operation, whole machine controlled by frequency changer;

>It consists of the automatic filling, dosing, forming, sealing, batch printing, easy tear notch, number, finished products

output etc;

>The horizontal sealing frame uses the single servo motor driver controlling with reliable & brief construction;

>The film-pulling is in stability, with eye mark photocell sensor by easy motion & amendment;

>The feeding frame uses the drawer type volumetric cup to weigh, non products throw off & non products crush during

feeding procedure, less wastage during packing, optimal adjustment and high precision in the field of the dosing system;

>It equips with the storage hopper on basis of continuous vacuum feeding conveyer, which provides automatic feeding

products;

>The dosing and filling construction can be dismantled with easy installation, clean disinfection;

>It collocates with two sets shutdown mechanism of horizontal sealing, to meet pre-set grouping & cutting and single bag

cutting in harmony with various request, the cutting position can be simply adjusted on the touch screen;

>The max wrapping film width will be 680mm, which makes 4 lines to 12lines package in terms of various bag width;

>It could be able to integrate with backward sort-out frame, automatic cartooning machine as one whole as to the complete

automatic package production line.

Usage:

>Suitable for non-sticky, loose granular products of pharmacy, foods, chemical package areas.